INSTRUMENTATION

CTL features a well-trained staff for strain gage applications. Our extensive experience is unmatched when it comes to applying gages on a variety of composite and metal specimens and structures.

TEST MACHINES

We provide 63 servo-hydraulic and 5 electro-mechanical test machines with load capability to 200,000 lb. Load, stroke, or material strain can control these machines. Each machine features a closed-loop controller and waveform generator that allows us to apply test loads in a variety of ways.

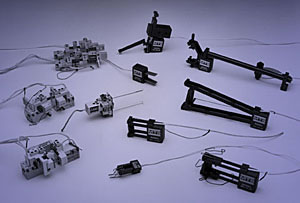

GRIPS AND FIXTURES

A large assortment of grips and fixtures lets us conduct tests from -320° F to 2800° F. Our internal machine shop provides great flexibility in tailoring our fixtures and grips to the specific material, temperature and condition being tested.

HEAT SOURCES

Several types of ovens and furnaces allow us to test up to 2800° F. We have numerous small 3-zone resistive-element furnaces to use with our hydraulic wedge grips, hydraulic button-head grips, self-aligning grips, and compressive fixturing. These small furnaces feature heating rates in excess of 600° F per minute with a maximum temperature of 2800° F. They achieve temperature distribution of better than ± 1% of test temperature over the measured gage section of the specimen.

EXTENSOMETERS

Our laboratories also feature several room-temperature and high-temperature extensometers with gage lengths from 0.5 to 2.0 in. We can calibrate all to ASTM E-83, Class B-1, in strain ranges from 1% to 50%. Our high-temperature extensometers are compatible with our furnaces, which allows us to measure strain over their entire temperature range.